DIY Battery Charging Station: Ever wished you could power up your tools, gadgets, or even electric vehicles without relying on the grid? Building a DIY battery charging station allows you to take control of your energy needs and create a reliable, customizable power source. From powering up your workshop to providing backup power during outages, a DIY battery charging station offers a wealth of possibilities.

This guide delves into the world of DIY battery charging stations, covering everything from essential components and safety considerations to advanced features and cost analysis. We’ll explore the different types of batteries compatible with these stations, discuss charging methods, and provide step-by-step instructions for building your own.

Introduction to DIY Battery Charging Stations

Building a DIY battery charging station offers numerous advantages, empowering you to charge various batteries efficiently and cost-effectively. It allows you to customize the charging process, ensuring optimal performance and longevity for your batteries.

A DIY battery charging station can be a versatile solution for charging various types of batteries, including:

Types of Batteries

The types of batteries you can charge using a DIY station are diverse and include:

- Lead-acid batteries: These are commonly used in cars, motorcycles, and other vehicles. They are relatively inexpensive and have a long lifespan.

- Lithium-ion batteries: These are increasingly popular due to their high energy density and lightweight design. They are used in smartphones, laptops, power tools, and electric vehicles.

- Nickel-cadmium (NiCd) batteries: These batteries are known for their durability and ability to withstand extreme temperatures. They are commonly found in older power tools and appliances.

- Nickel-metal hydride (NiMH) batteries: These batteries offer higher capacity and faster charging rates compared to NiCd batteries. They are widely used in portable electronics and hybrid vehicles.

Applications of DIY Battery Charging Stations

DIY battery charging stations find numerous applications in various settings, including:

- Electric Vehicles: With the growing popularity of electric vehicles, DIY charging stations can be a cost-effective alternative to commercial charging stations, especially for home charging.

- Power Tools: Charging power tool batteries at home can save time and money, eliminating the need to rely on external charging stations.

- Off-Grid Systems: In off-grid environments, DIY battery charging stations are essential for powering appliances and devices using renewable energy sources like solar panels or wind turbines.

- Emergency Preparedness: A DIY battery charging station can be crucial during power outages, ensuring you have backup power for essential devices and appliances.

Essential Components and Materials

A DIY battery charging station requires specific components to function correctly. The choice of components will depend on the type of batteries you intend to charge and the desired charging capacity.

This section will delve into the essential components and materials needed for building a DIY battery charging station, outlining their specifications, considerations, and common examples.

Power Supply

The power supply is the heart of the charging station, providing the necessary voltage and current to charge the batteries. Selecting the right power supply is crucial to ensure safe and efficient charging.

- Voltage: The voltage output of the power supply should match the voltage rating of the batteries being charged. For example, a 12V battery requires a 12V power supply.

- Current: The current output of the power supply determines the charging rate. Higher current ratings allow for faster charging but require thicker wires to handle the increased power flow.

- Capacity: The capacity of the power supply determines how long it can deliver the specified voltage and current before needing to be recharged itself. Consider the size and capacity of the batteries you intend to charge when choosing a power supply.

Common examples of power supplies used in DIY charging stations include:

- AC-DC Adapters: These adapters convert AC power from a wall outlet to DC power suitable for battery charging. They are widely available in various voltage and current ratings.

- Laptop Power Adapters: Many laptop power adapters can be repurposed for battery charging, providing a convenient and readily available power source.

- Benchtop Power Supplies: These adjustable power supplies offer greater control over voltage and current, allowing for precise charging adjustments.

Battery Charger Circuit

The battery charger circuit regulates the charging process, ensuring that the batteries receive the correct voltage and current for safe and efficient charging.

- Charging Algorithm: The charger circuit implements a specific charging algorithm to control the charging process, such as constant current, constant voltage, or a combination of both. This algorithm optimizes the charging process for different battery chemistries.

- Overcharge Protection: The charger circuit includes overcharge protection to prevent the batteries from being overcharged, which can damage them. This protection typically involves limiting the charging current or voltage when the battery reaches a certain level of charge.

- Overdischarge Protection: The charger circuit may also include overdischarge protection to prevent the batteries from being discharged below a safe level. This protection typically involves cutting off the charging current or voltage when the battery voltage drops below a certain threshold.

Commonly used components in battery charger circuits include:

- Transistors: Transistors act as switches to control the flow of current to the batteries.

- Diodes: Diodes prevent reverse current flow and protect the circuit from voltage spikes.

- Resistors: Resistors limit the current flow to the batteries and can be used to set the charging rate.

- Capacitors: Capacitors store energy and can be used to smooth out voltage fluctuations.

Connectors and Wires

Connectors and wires facilitate the connection between the power supply, the charger circuit, and the batteries. Choosing the right connectors and wires is crucial for ensuring a secure and reliable connection.

- Connectors: The type of connectors used will depend on the batteries being charged and the power supply. Common connectors include banana plugs, alligator clips, and terminal blocks.

- Wires: The wire gauge should be appropriate for the current rating of the power supply and the charging rate. Thicker wires are required for higher current ratings to prevent overheating and voltage drop.

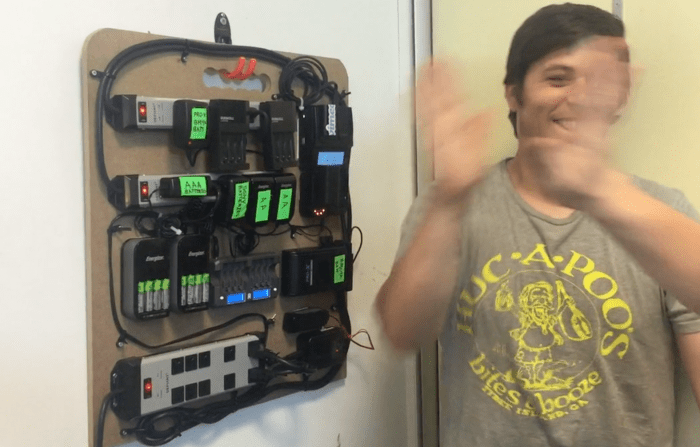

Enclosure

An enclosure provides protection for the charging station components and ensures safe operation.

- Material: The enclosure material should be non-conductive and durable, such as plastic or metal.

- Size: The enclosure should be large enough to accommodate all the components comfortably.

- Ventilation: Adequate ventilation is crucial to prevent overheating, especially for higher-power charging stations.

Common examples of enclosures used in DIY charging stations include:

- Project Boxes: These readily available boxes are ideal for small to medium-sized charging stations.

- Junction Boxes: Larger junction boxes can accommodate more complex charging stations with multiple batteries and circuits.

- Custom-Made Enclosures: For more elaborate charging stations, custom-made enclosures can be designed and fabricated to meet specific requirements.

Safety Considerations

Safety is paramount when building and using a DIY battery charging station.

- Proper Wiring: Ensure all connections are properly wired to prevent short circuits and electrical hazards.

- Insulation: Use insulated wires and connectors to prevent accidental contact with live components.

- Grounding: Ground the enclosure and all metal parts to prevent electric shock.

- Ventilation: Ensure adequate ventilation to prevent overheating and potential fire hazards.

Safety Precautions and Considerations: Diy Battery Charging Station

Building a battery charging station involves working with electricity and batteries, both of which can be hazardous if not handled properly. It’s crucial to prioritize safety throughout the project to prevent accidents and ensure a safe charging experience.

Working with Electricity, Diy battery charging station

Understanding the risks associated with electricity is essential. Here are some crucial precautions to take:

- Always work with the power disconnected. Before starting any wiring or component installation, ensure the power supply to the charging station is turned off and disconnected from the main power source.

- Use appropriate tools and equipment. Employ insulated tools, such as screwdrivers and wire cutters, to minimize the risk of electrical shock. Always use tools in good condition, and inspect them regularly for damage or wear.

- Avoid contact with live wires. Never touch any exposed wires or components while the power is on. Always double-check that the power is off before working on any part of the charging station.

- Use proper grounding techniques. Grounding is critical to prevent electrical shocks and protect against short circuits. Ensure all components are properly grounded to a dedicated ground wire connected to the main electrical panel.

- Work in a dry environment. Avoid working with electricity in wet or damp conditions, as water can conduct electricity and increase the risk of electric shock.

- Wear appropriate safety gear. When working with electricity, always wear safety glasses, insulated gloves, and non-conductive footwear. These precautions will help protect you from electrical hazards.

Working with Batteries

Batteries, especially lithium-ion batteries, can be hazardous if not handled correctly.

- Avoid overcharging or over-discharging. Overcharging can lead to battery damage and potential fire hazards, while over-discharging can shorten battery lifespan. Use a reliable battery management system (BMS) to monitor and control battery charging and discharging.

- Handle batteries with care. Avoid dropping or crushing batteries, as this can damage the internal components and increase the risk of fire. Always handle batteries gently and avoid exposing them to excessive heat.

- Store batteries properly. Store batteries in a cool, dry place, away from direct sunlight and heat sources. Do not store batteries in a confined space, as this can increase the risk of fire in case of a battery malfunction.

- Dispose of batteries properly. Do not throw batteries in the trash. Dispose of batteries according to local regulations and recycle them whenever possible. Batteries contain hazardous materials that can pollute the environment if not disposed of properly.

Wiring Practices and Grounding

Proper wiring and grounding are crucial for safety and functionality.

- Use appropriate wire gauges. Select wire gauges based on the current carrying capacity required for the charging station. Using undersized wires can lead to overheating and potential fire hazards. Consult electrical wiring codes and standards for appropriate wire gauge selection.

- Use insulated wire. Always use insulated wire to prevent electrical shocks and short circuits. Ensure the insulation is intact and not damaged.

- Use proper connectors and terminals. Use high-quality connectors and terminals designed for the specific application. Ensure proper connections and tighten all screws and terminals securely.

- Avoid loose connections. Loose connections can lead to overheating, sparking, and potential fire hazards. Ensure all connections are secure and properly tightened.

- Use a dedicated circuit. Install a dedicated circuit for the charging station, separate from other electrical appliances. This will prevent overloading the circuit and ensure sufficient power for charging.

- Ground the charging station. Grounding is crucial for safety. Connect the charging station’s ground wire to a dedicated ground wire connected to the main electrical panel. Ensure the ground connection is secure and properly installed.

Design and Construction Process

The heart of your DIY battery charging station lies in its design and construction. This section will guide you through creating a basic circuit diagram and provide a step-by-step guide for building your charging station. We’ll also share tips and tricks to optimize its performance and ensure safety.

Basic Circuit Diagram

A basic battery charging station typically involves a power supply, a current limiting resistor, and a charging circuit. The power supply provides the necessary voltage and current to charge the battery, while the current limiting resistor ensures that the charging current does not exceed the battery’s maximum charging rate. The charging circuit monitors the battery’s voltage and current, and automatically adjusts the charging process as needed.

Here’s a simple circuit diagram:

- Power Supply: The power supply is the source of energy for the charging station. It should provide a voltage and current rating that is compatible with the battery being charged. For example, a 12V battery might require a 12V power supply with a current rating of at least 2A.

- Current Limiting Resistor: The current limiting resistor is used to control the charging current. The value of the resistor will depend on the battery’s maximum charging rate. For example, a battery with a maximum charging rate of 1A might require a 10-ohm resistor.

- Charging Circuit: The charging circuit is responsible for monitoring the battery’s voltage and current, and automatically adjusting the charging process as needed. A simple charging circuit can be built using a few transistors and diodes. More sophisticated charging circuits might include features such as overcharge protection and temperature monitoring.

Step-by-Step Construction Guide

Building a DIY battery charging station requires careful attention to detail and adherence to safety guidelines. The following steps provide a general framework for the construction process:

- Gather the necessary materials: This includes the power supply, current limiting resistor, charging circuit components, a suitable enclosure, wires, connectors, and any other tools or materials needed for assembly.

- Assemble the charging circuit: Connect the components of the charging circuit according to the chosen circuit diagram. Ensure all connections are secure and properly insulated.

- Mount the components: Secure the components within the enclosure, leaving sufficient space for ventilation and wiring.

- Connect the power supply: Connect the power supply to the charging circuit, ensuring that the polarity is correct.

- Connect the battery terminals: Connect the battery terminals to the appropriate terminals on the charging circuit. Again, ensure that the polarity is correct.

- Test the charging station: Before using the charging station, it’s crucial to test it with a known good battery. Monitor the charging process and ensure that the battery is charging properly.

Tips for Optimization

- Use high-quality components: Invest in reliable power supplies, resistors, and charging circuit components for optimal performance and longevity.

- Choose the right charging current: Ensure the charging current is within the battery’s specifications. Overcharging can damage the battery.

- Monitor the charging process: Regularly check the battery’s voltage and current during charging to ensure it’s charging properly.

- Add safety features: Consider incorporating safety features such as overcharge protection, short circuit protection, and temperature monitoring.

By following the guidelines Artikeld in this guide, you can build a DIY battery charging station that meets your specific needs and empowers you with energy independence. Whether you’re a seasoned DIY enthusiast or a curious beginner, this project offers a rewarding journey into the world of renewable energy and personalized power solutions.

Building a DIY battery charging station can be a fun and rewarding project, especially if you’re looking for a way to organize and manage your devices. You can find plenty of resources online to guide you through the process, and even get inspiration from platforms like lialda , which offers educational content on a variety of topics, including DIY projects.

With a little planning and effort, you can create a charging station that fits your needs and style, making it easier than ever to keep your devices powered up.