DIY 3D print enclosure is a game-changer for any 3D printing enthusiast. This guide delves into the process of designing, printing, and assembling a custom enclosure for your 3D printer, offering a comprehensive journey from initial concept to finished product.

Building a 3D printed enclosure not only enhances your printer’s performance but also adds a personalized touch to your workspace. By controlling the environment around your 3D printer, you can improve print quality, reduce noise, and even add features like lighting and ventilation.

Designing a 3D Printed Enclosure

Designing a 3D printed enclosure is a rewarding process that allows for highly customized solutions. You can create a unique enclosure that perfectly fits your needs and aesthetic preferences.

Using CAD Software for Enclosure Design

CAD software is essential for designing 3D printed enclosures. It provides the tools needed to create detailed models and ensure they are printable.

Here is a step-by-step guide for designing a 3D printed enclosure using CAD software:

- Start with a Sketch: Begin by sketching out your enclosure design on paper. Consider the dimensions, shape, and any desired features. This helps you visualize the final product and identify any potential issues early on.

- Create a 3D Model: Use CAD software to translate your sketch into a 3D model. There are various software options available, such as Fusion 360, SolidWorks, and Tinkercad. Each program offers different features and learning curves, so choose one that aligns with your skill level and project requirements.

- Define Dimensions: Accurately define the dimensions of your enclosure. This includes the length, width, height, and any internal compartments or features. Ensure that the dimensions are suitable for the components you plan to house within the enclosure.

- Add Features: Incorporate necessary features into your design, such as ventilation holes, cable management channels, and mounting points. These features ensure proper functionality and ease of assembly.

- Check for Print Feasibility: Before sending your design to a 3D printer, review the model for printability. Consider factors such as overhangs, support structures, and wall thickness. Ensure that the design is within the capabilities of your printer and chosen filament.

- Prepare for Printing: Once you are satisfied with your design, export it in a format compatible with your 3D printer. The most common format is STL, which represents the model as a series of triangles. You may also need to prepare support structures or adjust the model for optimal printing.

Incorporating Features

Adding features to your 3D printed enclosure enhances its functionality and aesthetics.

Ventilation

Ventilation is crucial for preventing overheating, especially for enclosures housing electronic components.

- Design Ventilation Holes: Strategically place ventilation holes in your enclosure design to allow for airflow. The size and placement of these holes depend on the heat generated by the components inside.

- Consider Fans: For enclosures generating significant heat, consider incorporating fans to enhance airflow. Ensure the fan size and mounting points are included in your design.

Cable Management

Efficient cable management is essential for a neat and organized enclosure.

- Design Channels: Include channels or grooves in your design to route cables neatly. This prevents tangles and ensures easy access for maintenance.

- Use Cable Ties: Consider adding tie-down points or cable clamps for securing cables within the enclosure. These features help maintain a tidy and organized cable arrangement.

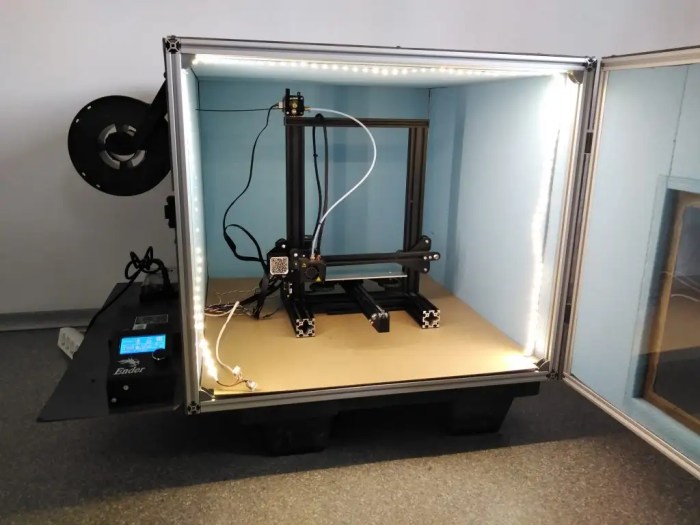

Lighting

Lighting can enhance the visibility of components within the enclosure.

- LED Strips: Integrate LED strips into your design for ambient lighting. Consider the placement and power requirements for the LED strips.

- Diffusers: If using bright LEDs, consider incorporating diffusers to soften the light and reduce glare.

Parametric Modeling

Parametric modeling is a powerful technique used in CAD software that allows you to create customizable designs.

- Dimensions as Variables: In parametric modeling, dimensions are defined as variables. This means you can easily adjust the size and shape of your enclosure by changing the values of these variables.

- Create Customizable Designs: Parametric modeling allows you to create a single design that can be easily adapted to different needs. For example, you can create a parametric enclosure design that can be customized to fit different electronics or components.

- Efficient Design Iteration: Parametric modeling simplifies the design iteration process. By changing the values of the variables, you can quickly explore different design variations and optimize your enclosure for specific requirements.

Materials for 3D Printed Enclosures

Choosing the right material for your 3D printed enclosure is crucial for its functionality and durability. Different materials have varying properties that make them suitable for different applications. Let’s explore some popular choices and their characteristics.

PLA (Polylactic Acid)

PLA is a widely used material for 3D printing due to its affordability, ease of printing, and biodegradability. It’s a good choice for enclosures that don’t require extreme strength or heat resistance.

- Strength: PLA is relatively strong, but it can be brittle, especially at low temperatures. It’s best suited for enclosures that won’t experience significant impact or stress.

- Heat Resistance: PLA has a low heat distortion temperature (around 60°C). It’s not suitable for enclosures that will be exposed to high temperatures.

- Printability: PLA is easy to print with most 3D printers. It has a good layer adhesion and a smooth finish.

ABS (Acrylonitrile Butadiene Styrene)

ABS is a more robust material than PLA, known for its strength and impact resistance. It’s a good option for enclosures that need to withstand some physical stress.

- Strength: ABS is tougher than PLA and can handle more impact. It’s a good choice for enclosures that will be subjected to bumps or drops.

- Heat Resistance: ABS has a higher heat distortion temperature than PLA (around 105°C), making it suitable for enclosures that will be exposed to moderate heat.

- Printability: ABS can be more challenging to print than PLA. It requires a heated bed and enclosure to prevent warping.

PETG (Polyethylene Terephthalate Glycol)

PETG is a versatile material that offers a good balance of strength, flexibility, and heat resistance. It’s a popular choice for enclosures that require a combination of these properties.

- Strength: PETG is stronger and more impact-resistant than PLA. It’s a good choice for enclosures that will be exposed to some physical stress.

- Heat Resistance: PETG has a high heat distortion temperature (around 80°C), making it suitable for enclosures that will be exposed to moderate heat.

- Printability: PETG is generally easy to print with most 3D printers. It has good layer adhesion and a smooth finish.

Nylon (Polyamide)

Nylon is a strong and durable material known for its high impact resistance and excellent wear properties. It’s a good option for enclosures that will be subjected to heavy use or harsh environments.

- Strength: Nylon is one of the strongest materials for 3D printing. It can withstand significant impact and stress.

- Heat Resistance: Nylon has a high heat distortion temperature (around 170°C), making it suitable for enclosures that will be exposed to high temperatures.

- Printability: Nylon can be challenging to print with some 3D printers. It requires specialized settings and a heated bed.

Selecting the Best Material

To choose the best material for your enclosure, consider the following factors:

- Application: What will the enclosure be used for? What kind of environment will it be exposed to?

- Strength Requirements: How much impact or stress will the enclosure need to withstand?

- Heat Resistance: What temperature range will the enclosure be exposed to?

- Printability: What type of 3D printer do you have? What are its capabilities?

- Cost: How much are you willing to spend on the material?

Printing a 3D Printed Enclosure

Printing a 3D printed enclosure requires careful consideration of your 3D printer’s settings and the specific design of your enclosure. The goal is to achieve a strong, durable, and aesthetically pleasing final product. This section will guide you through the process of setting up your 3D printer and optimizing printing parameters to achieve the best results.

Printing Parameters

Printing parameters are crucial for achieving the desired quality and strength of your 3D printed enclosure. These parameters determine the thickness of each layer, the amount of material used to fill the object, and the level of support structures required.

- Layer Height: The layer height determines the thickness of each layer of printed material. A lower layer height generally produces smoother surfaces and finer details. For enclosures, a layer height of 0.15 to 0.2 mm is a good starting point. A lower layer height will result in a smoother finish, but it will take longer to print. A higher layer height will print faster, but the surface may be less smooth.

- Infill Density: Infill density refers to the amount of material used to fill the inside of your printed object. Higher infill densities provide greater strength and rigidity, but they also increase the amount of material used and the printing time. For enclosures, an infill density of 20% to 30% is generally sufficient for structural integrity. Higher infill densities can be used for areas that require extra strength or rigidity, such as the corners of the enclosure.

- Support Structures: Support structures are temporary structures that help to support overhangs and other difficult-to-print features during the printing process. Support structures are generated by the 3D printing software and are typically made of a soluble material that can be easily removed after printing. Support structures are essential for enclosures with complex geometries or features that overhang. If your enclosure has overhangs, you will need to use support structures.

Troubleshooting Common Printing Problems

Printing problems can occur during the 3D printing process. Here are some common printing problems and tips for troubleshooting them:

- Layer Adhesion Problems: Layer adhesion problems occur when the layers of printed material do not adhere properly to each other. This can result in gaps or holes in the printed object. Common causes include:

- Incorrect Print Bed Temperature: The print bed temperature should be set to the appropriate temperature for the filament being used. Refer to the filament manufacturer’s recommendations for the optimal print bed temperature.

- Dirty Print Bed: A dirty print bed can prevent the first layer from adhering properly. Clean the print bed with a cleaning solution recommended for your print bed material.

- Improper Bed Leveling: The print bed must be level to ensure proper adhesion. If the print bed is not level, the first layer will not adhere properly. Level the print bed using the methods provided by your 3D printer manufacturer.

- Filament Jams: Filament jams can occur when the filament gets stuck in the extruder or the nozzle. Common causes include:

- Clogged Nozzle: A clogged nozzle can prevent the filament from flowing properly. Clean the nozzle with a needle or a nozzle cleaning tool.

- Incorrect Filament Diameter: Ensure that the filament diameter is compatible with the extruder and the nozzle. If the filament diameter is too large or too small, it can cause jams.

- Bent Filament Path: The filament path should be smooth and free of obstructions. If the filament path is bent or obstructed, it can cause jams.

- Print Quality Issues: Print quality issues can include uneven surfaces, stringing, and warping. Common causes include:

- Incorrect Extruder Temperature: The extruder temperature should be set to the appropriate temperature for the filament being used. Refer to the filament manufacturer’s recommendations for the optimal extruder temperature.

- Incorrect Flow Rate: The flow rate determines the amount of filament extruded per unit of time. Adjust the flow rate to ensure that the filament is being extruded at the correct rate.

- Poor Cooling: Proper cooling is essential for achieving good print quality. Ensure that the cooling fan is working properly and that there is adequate airflow around the print.

Assembling and Finishing a 3D Printed Enclosure

The final step in creating a 3D printed enclosure is assembling and finishing the printed parts. This involves joining the individual components, smoothing out any imperfections, and adding custom features to enhance its look and functionality.

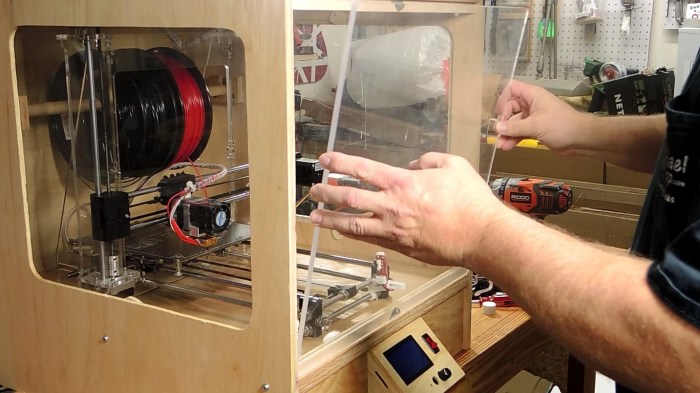

Assembling the Printed Parts

Assembling the printed parts typically involves joining them using mechanical fasteners, adhesives, or a combination of both. The choice of assembly method depends on the design of the enclosure and the desired level of permanence.

- Mechanical Fasteners: Screws, nuts, bolts, and other mechanical fasteners offer a strong and easily removable connection. This method is suitable for enclosures that need to be disassembled for maintenance or modification.

- Adhesives: Epoxy, superglue, and other adhesives provide a permanent bond between the printed parts. This method is ideal for enclosures that require a smooth and seamless finish.

- Snap-Fit Design: Some enclosures are designed with interlocking features that allow the parts to snap together without the need for additional fasteners. This method is quick and easy, but may not be as strong as other methods.

Smoothing and Finishing the Printed Surface

3D printed surfaces often have a rough texture due to the layer-by-layer printing process. Smoothing and finishing the surface improves the appearance and durability of the enclosure.

- Sanding: Using sandpaper of varying grits can smooth out the surface and remove any imperfections. Start with a coarser grit and gradually move to a finer grit for a smoother finish.

- Priming and Painting: Applying a primer before painting helps to create a smooth surface for the paint to adhere to. A wide range of paints can be used to color and enhance the enclosure’s appearance.

- Epoxy Resin: Applying a thin layer of epoxy resin over the surface can create a smooth and glossy finish. This method is especially useful for enclosures that require a durable and water-resistant surface.

Adding Custom Features and Accessories

Adding custom features and accessories to the enclosure can personalize its look and functionality.

- Custom Panels: 3D printed panels can be designed and added to the enclosure to create custom interfaces, vents, or decorative elements.

- LED Lighting: Adding LED lights inside or outside the enclosure can enhance its appearance and provide functional lighting.

- Handles and Knobs: Handles and knobs can be added to the enclosure to make it easier to open and close.

Enhancing Functionality with Electronics

Adding electronics to your 3D printed enclosure can transform it from a simple container into a functional and interactive device. You can integrate components like temperature sensors, fans, and lighting to monitor, control, and enhance the environment inside your enclosure. This section explores how to incorporate these electronics, connect them to a control system, and design custom 3D printed mounts and enclosures for them.

Integrating Electronic Components

Incorporating electronics into your 3D printed enclosure can enhance its functionality and create a more interactive experience. These components can monitor, control, and enhance the environment within the enclosure, providing valuable data or automated control mechanisms.

- Temperature Sensors: Temperature sensors, such as the popular LM35 or DS18B20, can be used to monitor the temperature inside the enclosure. This information can be used to trigger a fan or other cooling mechanisms if the temperature exceeds a set threshold.

- Fans: Fans can be integrated to provide ventilation and cooling inside the enclosure. They can be controlled by a microcontroller based on the temperature readings from a sensor or by a timer for regular ventilation.

- Lighting: LEDs can be used for internal lighting within the enclosure, providing visibility for tasks or creating a visually appealing effect. These LEDs can be controlled by a microcontroller or a simple switch.

Connecting and Controlling Electronic Components

The heart of your electronic system is the microcontroller, which receives data from sensors, processes it, and sends commands to actuators like fans or LEDs.

- Arduino: Arduino is a popular platform for hobbyists and makers due to its ease of use and extensive community support. It offers a range of boards with different functionalities, making it suitable for a wide range of projects.

- Raspberry Pi: Raspberry Pi is a credit card-sized computer that can run a full operating system. It’s a more powerful platform compared to Arduino and can handle complex tasks like data logging and networking.

3D Printed Mounts and Enclosures for Electronics

Designing and printing custom mounts and enclosures for your electronic components can significantly enhance the aesthetics and functionality of your project.

- Mounts: 3D printing allows you to create custom mounts for sensors, fans, and other components, ensuring a secure and aesthetically pleasing fit within the enclosure. You can design mounts with specific angles and dimensions to optimize the placement and function of the components.

- Enclosures: You can 3D print custom enclosures for your electronic components, providing protection and a professional look. These enclosures can be designed with ventilation slots, cable management channels, and other features to enhance the functionality of your electronics.

Safety Considerations for 3D Printed Enclosures

While 3D printing offers a fantastic way to create custom enclosures, it’s crucial to prioritize safety. Enclosures house electronics and components, and neglecting safety precautions can lead to fire hazards or damage.

Fire Safety in 3D Printed Enclosures

The materials used in 3D printing can be flammable, especially when exposed to high temperatures.

It’s crucial to take steps to minimize fire risks.

- Use Fire-Resistant Materials: Opt for 3D printing filaments with inherent fire-resistant properties. Materials like nylon, polycarbonate, and ABS are generally more flame-retardant than PLA.

- Ventilation: Ensure adequate ventilation to dissipate heat generated during printing and operation. A well-ventilated enclosure will help prevent overheating.

- Avoid Overheating: Avoid overloading the enclosure with high-power electronics that could generate excessive heat. Consider using heat sinks or fans to dissipate heat effectively.

- Keep Flammables Away: Store flammable materials like solvents, cleaners, or aerosols away from the enclosure and the printing area.

- Fire Extinguisher: Keep a fire extinguisher readily accessible in case of an emergency.

Inspiration and Examples: Diy 3d Print Enclosure

The world of 3D printed enclosures is brimming with creativity and innovation. From sleek and minimalist designs to intricate and functional creations, these enclosures showcase the versatility and potential of 3D printing.

Examples of Unique and Innovative 3D Printed Enclosures

These enclosures demonstrate the vast range of possibilities and aesthetics achievable with 3D printing:

- Modular Enclosure: A modular enclosure allows for easy customization and expansion. The enclosure consists of interlocking panels that can be arranged in various configurations to suit different needs and sizes. This design is ideal for projects that require flexibility and adaptability.

- Organic Enclosure: Inspired by natural forms, an organic enclosure features flowing lines and curves. This type of enclosure can create a visually striking and unique aesthetic. It can be used for applications where a more artistic and unconventional design is desired.

- Geometric Enclosure: Geometric enclosures utilize precise angles and shapes, creating a modern and minimalist aesthetic. This type of enclosure is often used for electronics projects where a clean and functional design is essential.

Examples of Enclosures Designed for Specific 3D Printer Models or Applications

- Enclosures for Desktop 3D Printers: These enclosures are designed to improve the performance and reliability of desktop 3D printers. They can help to reduce ambient temperature fluctuations, minimize dust and debris, and provide a more controlled printing environment. These enclosures often incorporate features like ventilation, lighting, and integrated filament storage.

- Enclosures for Industrial 3D Printers: Industrial 3D printers often require specialized enclosures to meet the demands of demanding manufacturing environments. These enclosures may be designed for specific applications, such as high-temperature printing or hazardous material handling. They often incorporate features like safety interlocks, emergency shut-off mechanisms, and robust construction.

- Enclosures for Specific Applications: 3D printed enclosures can be tailored to specific applications, such as medical devices, consumer electronics, and industrial automation. These enclosures are often designed to meet specific performance requirements, such as water resistance, shock resistance, and electromagnetic interference (EMI) shielding.

Online Resources and Communities for 3D Printed Enclosure Designs

Sharing and collaboration are key aspects of the 3D printing community. These online resources and communities provide a platform for enthusiasts to share their designs, seek inspiration, and learn from each other:

- Thingiverse: A vast online repository of 3D printable designs, including a wide range of enclosures for various applications.

- Printables: Another popular platform for sharing and discovering 3D printable designs, with a dedicated section for enclosures.

- 3D Printing Forums: Online forums dedicated to 3D printing offer opportunities for discussion, sharing designs, and seeking advice from experienced users.

- Social Media Groups: Facebook groups and other social media platforms dedicated to 3D printing provide a space for sharing projects, exchanging ideas, and connecting with other enthusiasts.

Troubleshooting and Maintenance

Even the most meticulously designed and printed 3D enclosure can encounter issues over time. Understanding common problems and implementing preventive measures can significantly extend the life of your enclosure and ensure its continued functionality.

Identifying and Addressing Common Issues

A variety of factors can contribute to problems with 3D printed enclosures. Here are some common issues and their potential solutions:

- Cracking or warping: This can occur due to poor print quality, improper material selection, or excessive heat exposure. Ensure your printer settings are optimized for the chosen filament, use a heated bed if necessary, and avoid exposing the enclosure to extreme temperatures.

- Loose or broken connections: If components within the enclosure become loose or break, it can disrupt functionality. Carefully inspect all connections and fasteners. If a part is broken, consider replacing it with a new print, or use epoxy or superglue to repair it.

- Dust and debris accumulation: Dust and debris can interfere with moving parts and electronics. Regularly clean the enclosure with a soft cloth or compressed air to remove dust and debris. Avoid using harsh chemicals that can damage the print.

- Print quality issues: Poor print quality can result in weak or fragile parts. Ensure your printer settings are optimized for the chosen filament, calibrate the printer regularly, and use high-quality filament.

Maintaining the Enclosure

Preventative maintenance is key to prolonging the life of your 3D printed enclosure. Here are some tips:

- Regular cleaning: Dust and debris can accumulate over time, potentially leading to malfunctions. Regularly clean the enclosure with a soft cloth or compressed air to remove dust and debris.

- Inspecting for damage: Regularly inspect the enclosure for any signs of cracking, warping, or loose connections. Address any issues promptly to prevent further damage.

- Proper storage: When not in use, store the enclosure in a clean, dry environment to prevent dust and moisture accumulation.

- Avoid excessive heat exposure: Prolonged exposure to high temperatures can cause warping and degradation of the plastic. Keep the enclosure away from direct sunlight or heat sources.

Repairing and Replacing Damaged Parts

In the event of a damaged part, there are several options:

- Reprint the part: If the original print file is available, simply reprint the damaged part. Ensure the new print is properly adhered to the rest of the enclosure.

- Use epoxy or superglue: For minor cracks or breaks, epoxy or superglue can be used to repair the damage. Ensure the adhesive is compatible with the plastic used for the enclosure.

- Replace the part with a different material: If the original part is prone to cracking or warping, consider replacing it with a print made from a stronger or more heat-resistant material.

Future Trends in 3D Printed Enclosures

The world of 3D printing is constantly evolving, and 3D printed enclosures are no exception. Advancements in technology and materials are paving the way for enclosures that are lighter, stronger, more customizable, and more functional than ever before. These advancements are opening up new possibilities for using 3D printed enclosures in a wide range of applications.

Emerging Technologies and Materials

Emerging technologies and materials are playing a key role in shaping the future of 3D printed enclosures.

- Multi-material 3D printing: This technology allows for the creation of enclosures that incorporate multiple materials, such as plastics, metals, and composites. This opens up new possibilities for designing enclosures with specific properties, such as strength, flexibility, and heat resistance.

- 4D printing: 4D printing involves the use of materials that change shape in response to external stimuli, such as heat or light. This technology could be used to create enclosures that can adapt to changing environments or conditions.

- Bioprinting: Bioprinting involves the use of living cells to create 3D structures. This technology has the potential to revolutionize the way we design and manufacture enclosures for medical and other applications.

- Advanced materials: Researchers are constantly developing new materials that are specifically designed for 3D printing. These materials include high-performance plastics, ceramics, and metals that offer improved strength, durability, and heat resistance.

Potential Applications of 3D Printed Enclosures, Diy 3d print enclosure

The use of 3D printed enclosures is expanding rapidly. These enclosures are becoming increasingly popular in various industries, including:

- Electronics: 3D printed enclosures are ideal for housing electronic components, as they can be customized to fit specific requirements. They are also lightweight and durable, making them suitable for use in a variety of applications.

- Medical devices: 3D printed enclosures are being used to create custom-fit medical devices, such as prosthetics and implants. The ability to create complex geometries and intricate designs makes 3D printing an ideal technology for these applications.

- Automotive: 3D printed enclosures are being used to create lightweight and aerodynamic components for cars and other vehicles. This technology is also being used to create custom-fit enclosures for automotive electronics.

- Aerospace: 3D printed enclosures are being used to create lightweight and durable components for spacecraft and other aerospace applications. This technology is also being used to create custom-fit enclosures for aerospace electronics.

- Consumer products: 3D printed enclosures are being used to create a wide range of consumer products, such as toys, furniture, and home appliances. This technology allows for the creation of unique and personalized products that meet the specific needs of consumers.

Predictions for the Future of 3D Printing

The future of 3D printing is bright. Experts predict that the technology will continue to evolve rapidly, leading to:

- Increased affordability: The cost of 3D printing is expected to decrease, making it more accessible to businesses and individuals. This will lead to a wider adoption of 3D printing for a variety of applications.

- Improved speed and efficiency: 3D printing processes are expected to become faster and more efficient. This will allow for the rapid prototyping and production of 3D printed enclosures.

- Greater customization: 3D printing will allow for the creation of highly customized enclosures that meet specific needs. This will open up new possibilities for product design and innovation.

- Increased sustainability: 3D printing can be used to create products on demand, reducing waste and minimizing the environmental impact of manufacturing.

Creating a DIY 3D print enclosure is a rewarding project that empowers you to customize your printing experience. By combining design ingenuity with the power of 3D printing, you can build a functional and aesthetically pleasing enclosure that perfectly suits your needs.

Building a DIY 3D print enclosure can be a fun and rewarding project, especially if you want to control the environment for your prints. While you’re focusing on the enclosure, it’s important to remember the importance of proper ventilation, which is crucial for preventing the buildup of fumes, especially when working with materials like ABS plastic. For example, you might consider installing a fan to help circulate air and ensure that any potential toxins are quickly dispersed.

This is similar to how the antifungal medication voriconazole works to help prevent fungal infections by disrupting the growth of fungi. Once you’ve got the ventilation sorted, you can focus on other aspects of your DIY 3D print enclosure, like temperature control and sound dampening.